Ointment Cream Manufacturing Plant

Ointment Cream Manufacturing Plant Specification

- Material

- SS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Color

- Silver

- Warranty

- Yes

Ointment Cream Manufacturing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 2 Months

About Ointment Cream Manufacturing Plant

We offer a range of automatic ointment manufacturing plant that cater to the needs of pharmaceutical and Cosmetics industries.These plants are available in various batch capacities and are appreciated for its superior quality and excellent functionality. Our range is specially designed to take care of hygiene and low maintenance factor. In addition, we also custom designed these plants as per the details provided by the clients.

Application

- Pharmaceuticals: Creams, Gels, Sterile & Non Sterile Ointments and Biotech products.

- Cosmetics: Cold Creams, Hair Dye Cream, Conditioners, Lotions, Gels, Mascara make-up, Shampoo, Toothpaste.

Technical feature:

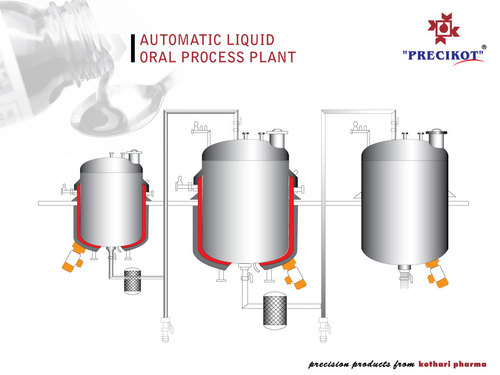

Main Vessel:

- Choice of various type of anchor design.

- Homogeniser (option) Top Entry, side Entry, Bottom Entry with circulation facility

- Hydraulic lid lifting for fast & easy cleaning of top dish & vessel.

- Load Cell for fast & accurate measuring system.

- Flexible product transfer pipe & fitting in case of load cell & hydraulic lifting.

- VFD for Anchor agitators to vary the RPM.

- VFD for Homogeniser to vary RPM.

- Specially Design drive assembly.

Wax vessel:

- Open top with top Entry agitator Cowl disc type or paddle with Slow Speed Anchor.

- Close top with top/bottom entry agitator Cowl disc type or propeller type stirrer.

Water Vessel:

- Open top with top entry propeller stirrer

- Close top with bottom or top entry propeller

Design Base:

- A Special pharmaceutical design enables application in biotechnical process. Material, surface as well as general design are in keeping with the GMP directives as well as the recommendations of the FDA & USFDA.

- Vessel design as per ASME guideline and tailor made design as per users / product Requirements.

- All vessel are per GMP regulations.

- Total plant is design & supplied as per CGMP guidelines

Advantages :

- Choice of various type of anchor design

- Simple to operate

- Flexible Configuration

- Fully Automated

- Fast product change over

- Rapid & effective cleaning CIP/SIP

- Integration into existing process control system

- Mixing, dispersing & homogenizing in one operation

- Homogenous product consistency without trapped air bubbles

Capacity Available:

- 5 Kg to 3000 Kg

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 2 Months

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oinment Section Category

Ointment Making Plant

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Computerized : No

Material : SS

Control System : Human Machine Interface

Warranty : Yes

Tube Filling Machine Single Head

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Computerized : No

Material : SS

Control System : Human Machine Interface

Warranty : Yes

Pilot Single Vessel

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Computerized : No

Material : SS

Control System : Human Machine Interface

Warranty : Yes

Heavy Duty Ointment Plant

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Computerized : No

Material : SS

Control System : Human Machine Interface

Warranty : Yes

|

KOTHARI PHARMA TECHNOLOGIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |